Application

The cabinet is designed for protection of objects and materials inside the work chamber from external and cross-contamination ensuring dustless pure air environment.

The cabinet is used for work with substances that are not hazardous to personnel.

The cabinet is used to equip individual work places in medical, pharmaceutical and other institutions with high requirements to air purity in the work zone.

Function

The cabinet is an enclosure with a front work opening through which an operator may perform manipulations inside the cabinet. The cabinet is designed to protect the product (from cross-contamination as well) and to exhaust contaminants produced during work with air displaced from the cabinet. The above is ensured by unidirectional air downflow inside the cabinet.

Standard Configuration

Work Chamber

- hinged front sash made of tempered glass; opening, closing and upholding is carried out by gas springs;

- damper against front window closing impact;

- side windows made of tempered glass;

- slanted front surface of the cabinet;

- LED lighting of the work chamber;

- one set of electric sockets in the work chamber (2 pcs. in the right part of the rear wall);

- airflow laminarization screen made of polymer micromesh;

- tabletop made of stainless steel (AISI 304);

- work opening screen for operator protection during UV light operation.

UV light

- UV light is located is the upper part of the work chamber rear wall and is covered with a protective grille made of stainless steel;

Supply and Exhaust Air Filtration System

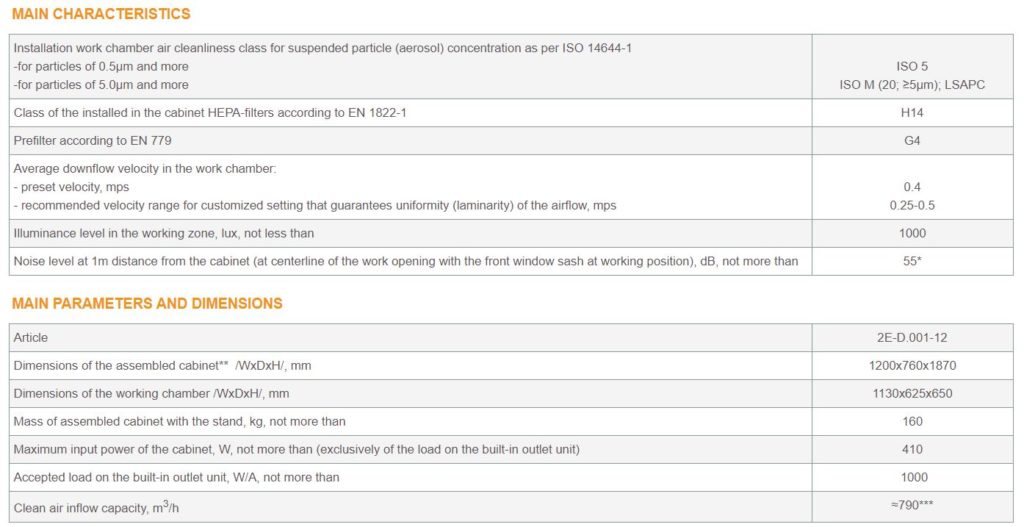

- supply air coming into the work chamber is cleaned by preliminary filter G4 and supply HEPA filter H14;

- two fans ensuring air supply into the cabinet.

Control System Components

- microprocessor control system;

- pushbutton control panel with LCD screen;

- airflow sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- fixed power cord.

Testing Components

- built-in outlet for sampling the air from the high-pressure plenum under the G4 filter for HEPA filter integrity testing.

Stand

- frame stand with footrest;

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.